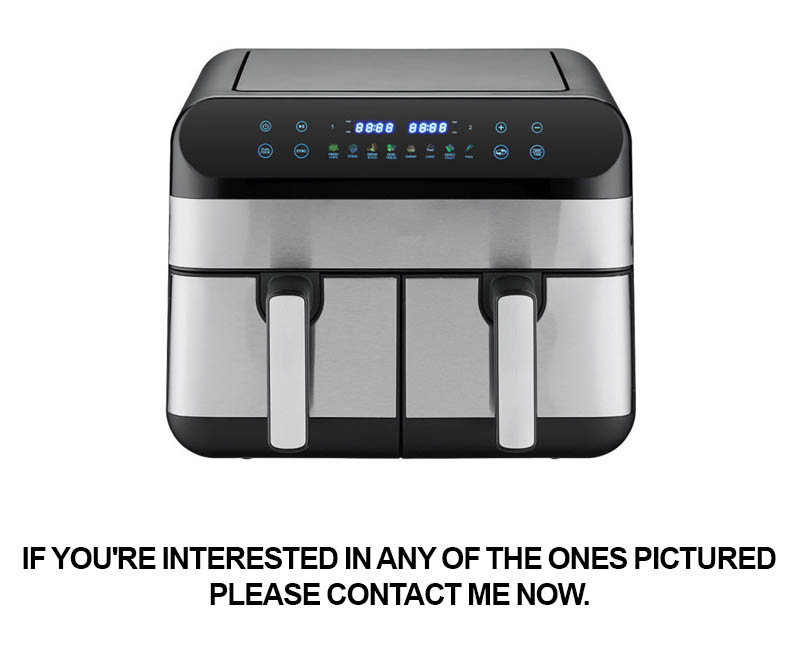

Air Fryer Supplier Best Practices: Quality Assurance, Timely Delivery, and Choosing a Reliable Partn

Ensuring product quality and maintaining delivery timelines are paramount for air fryer suppliers looking to build and sustain a trustworthy reputation in the market. Various strategies and practices help these suppliers achieve their goals, from implementing rigorous quality control mechanisms to leveraging advanced logistic solutions. For buyers seeking a reliable supplier, understanding these practices is crucial in making informed decisions that align with their needs and expectations.

Quality assurance begins long before an air fryer reaches the consumer. Suppliers typically start with stringent sourcing of raw materials, ensuring that all components meet industry standards and specifications. This involves working closely with material providers to guarantee consistent quality and reliability. Additionally, many suppliers have adopted comprehensive testing protocols throughout the manufacturing process. Each unit often undergoes multiple stages of inspection and performance testing to detect any defects or malfunctions early on. This meticulous approach minimizes the risk of faulty products reaching the end-user.

Another critical aspect is adherence to international quality certifications such as ISO 9001, CE, and RoHS. These certifications serve as benchmarks for quality and safety, providing an additional layer of credibility for both the supplier and the buyer. By complying with these standards, suppliers demonstrate their commitment to delivering high-quality products consistently.

In terms of delivery timelines, air fryer suppliers rely on efficient supply chain management and robust inventory control systems. Advanced planning and forecasting tools enable them to predict demand accurately and manage stock levels effectively. This proactive approach ensures that there is always sufficient inventory to meet customer orders without unnecessary delays. Furthermore, strategic partnerships with logistics providers play a significant role in streamlining the distribution process. Reliable shipping options and well-coordinated logistics networks help in reducing transit times and ensuring timely deliveries.

Buyers looking to choose a reliable air fryer supplier should consider several key aspects beyond just product quality and delivery speed. Firstly, it’s essential to evaluate the supplier’s experience and track record in the industry. A seasoned supplier with a proven history of satisfying customers is more likely to be dependable. Checking customer reviews and testimonials can provide insights into the supplier’s performance and customer satisfaction levels.

Another important factor is the supplier’s communication skills and responsiveness. Effective and transparent communication regarding order status, potential delays, and any issues that arise is vital for building trust and ensuring a smooth buying experience. Buyers should also inquire about the supplier’s after-sales support policies, including warranties, return policies, and customer service availability.

Additionally, assessing the supplier’s technological capabilities and innovation efforts can be beneficial. Suppliers who invest in research and development tend to stay ahead of industry trends and offer cutting-edge products. Visiting the supplier’s facilities or requesting virtual tours can also provide a firsthand look at their manufacturing processes and quality assurance measures.

Lastly, financial stability is a crucial consideration when selecting a supplier. A financially stable supplier is better equipped to handle unforeseen challenges and maintain consistent operations, ensuring that they can meet their obligations without disruptions.

In the end, while ensuring product quality and delivery timelines may seem challenging, air fryer suppliers employ a multifaceted approach that integrates stringent quality controls, advanced supply chain management, adherence to international standards, and strong logistical partnerships. For buyers, choosing a reliable supplier requires a thorough evaluation of experience, communication, after-sales support, technological innovation, and financial health. By carefully considering these factors, buyers can forge partnerships that lead to successful and sustained business outcomes.